Our Process

ON MARKING

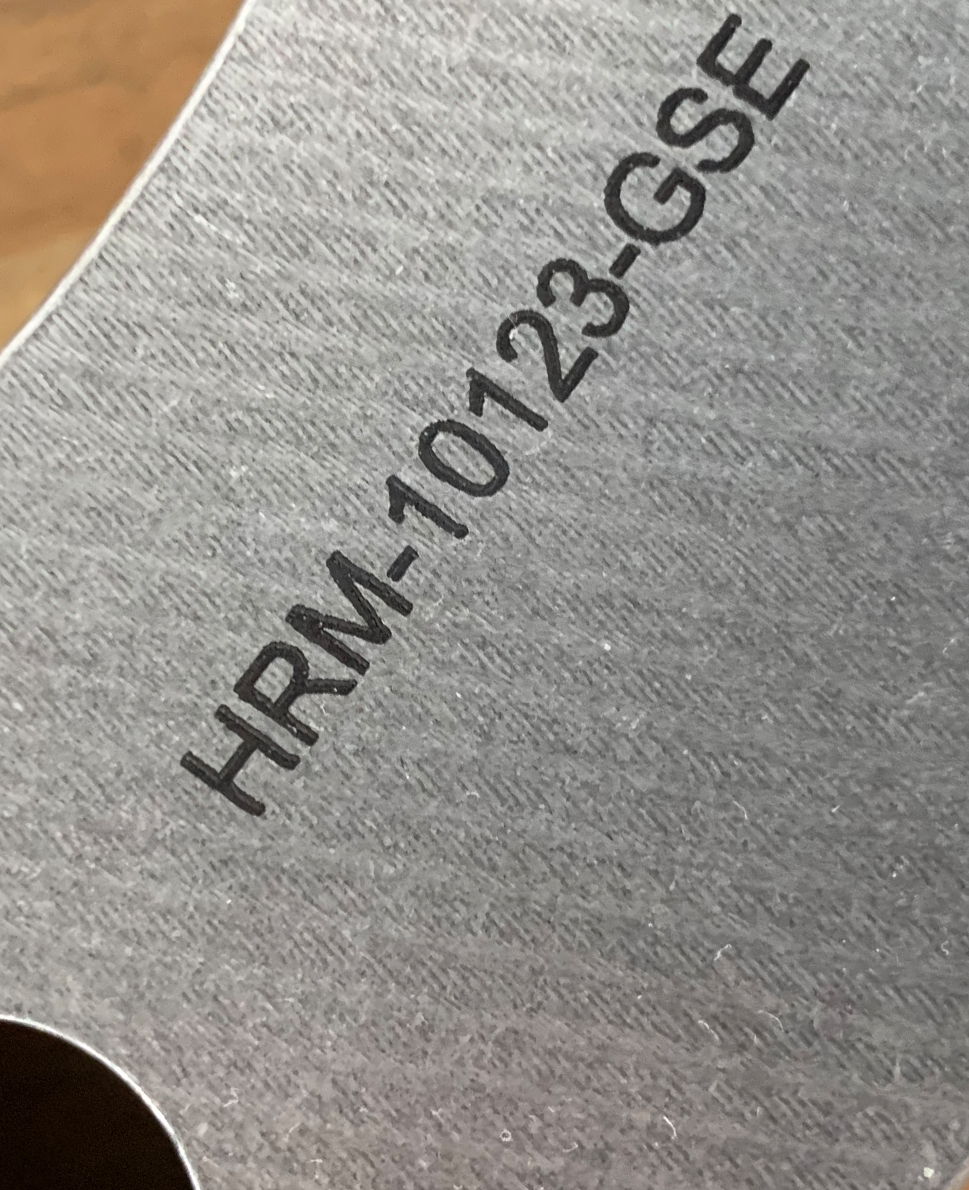

Direct part marking (DPM) is a process to permanently mark parts with product information including serial numbers, part numbers, date codes, and barcodes. This is done to allow the tracking of parts through the full life cycle.

Part marking is inevidible and required when identifying parts. There are several methods that can be used to ensure a durable long life cycle of the marking to match the life cycle of the part that is being marked. American Data Plates, Inc. offers the following processes in part marking:

Part marking is inevidible and required when identifying parts. There are several methods that can be used to ensure a durable long life cycle of the marking to match the life cycle of the part that is being marked. American Data Plates, Inc. offers the following processes in part marking:

- Pad Printing

- Laser Marking

- Screen Printing

- UV Printng

Pad printing and screen printing we utilize Nazdar inks, overcoats, thinners and hardners.

Direct Part

MARKING SERVICES

Marking method selection factors

The marking method depends on a number of different factors:

The marking method depends on a number of different factors:

- Part function

Non-intrusive marking methods are recommended for parts used in safety critical applications like aircraft engines or high pressure and high stress systems. - Part geometry

It is more difficult to place a Data Matrix on a curved surface than it is on a flat surface. - Surface

Highly polished metal surfaces should be textured to reduce glare prior to marking. The textured area should extend one symbol width beyond the borders of marking. - Part Size

When a 2D Symbol is used, the size of the part is not a relevant factor as the available marking area is reduced to below 1/4 inch square. - Operating environment / age life

It should be controlled, if the used marking method can survive in its intended environment and remain readable for the life cycle of the part.

Quick Links

Correspondence

Media & News

Legal Information